The AVL Industrial Dobby Loom offers a wide range of weaving options for industrial sampling or small scale production. The loom is fully automated with push-button control and utilizes powerloom technology to simulate hand weaving.

Computer Optimized Design

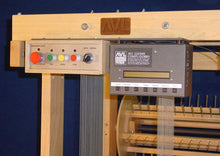

The lifting motion is controlled by a standard twenty-four harness AVL Compu-Dobby®. When linked to the controlling computer, patterns can be changed in a matter of seconds. A newly re-designed Dobby mechanism features a machined plate that rides on specially manufactured slide rods and linear bearings. These high-grade materials result in a smooth action which will require virtually no attention.

Advanced Pneumatic Drive The IDL is driven entirely by air. Using pneumatics in conjunction with advanced electronics increase longevity; decreases vibration; and makes the loom clean and easy-to-maintain.

Sensor Control: Another unique feature of the IDL is the strategic use of sensors throughout the loom. Photo sensors and reed switches are used to sense all motions and send them back to the control unit for constant monitoring of the system. The photo sensors, for example, are used to see whether there's a shuttle in a box. If the shuttle isn't seen there, it won't be thrown, which adds to the safety of the operator.

Color Selection: The IDL comes equipped with a 4x4 shuttle-box system. The color is controlled directly from the controlling computer. Color can be alternated automatically or defined on a pick by pick basis.

Each IDL is equipped with industrial-style adjustable temples. The number and intensity of the spiked rings can be changed for different fabric weights.

Push-Button Operation: A control panel in the center of the loom includes push-buttons for the following operations: start, pause, stop, and emergency stop. There is also a switch for toggling between automatic and manual operation.

In manual mode, each loom function can be individually controlled, including: advance, dobby, shuttle, and beater. So, the user can control each aspect of the weaving to make adjustments or changes as needed.

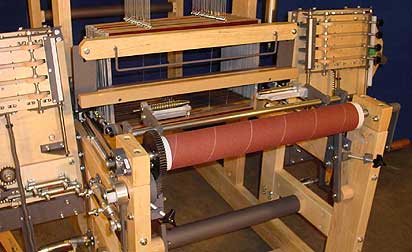

The IDL's four-by-four flyshuttle beater is a remarkably versatile device that saves time and money.

Warp Let-Off: Warp tension is controlled by AVL's celebrated Automatic Warp Tension system. The loom can use either one or two individually tensioned sectional or standard warp beams. AVL's tension system is highly sensitive and maintains a constant tension from start to finish.

Cloth Take-Up: A slip-free, gear-driven, take-up with a special sliding pick density system is a highlight of the loom. The pneumatically driven take-up is unique in the industry and provides a wide range of pickage.

Features

Features:

- Four by Four Flyshuttle System: up to seven color selections.

- Four Flyshuttles, 12 Bobbins: end-feed for optimal selvages, metal tipped for maximum life. Up to 7 different colors in the weft.

- Sectional Warping Beam, 1-Yard (hoops set at 2” sections, adjustable to 1”): fast warp changes. Loom can hold 2 1-yard beams or smaller.

- Automatic Cloth Storage System: advances Cloth Storage to eliminate slack with minimum tension.

- Automatic Pickage Advance System: adjustable.

- Pressure Roller: minimizes slippage to reduce cloth stress and maximum pickage control.

- Automatic Warp Let-Off System: dual tension arm system automatically adjusts to minimize warp stress.

- Temple Roller System: controls draw-in on the fly.

- 24 Harnesses: hardwood, aluminum, and stainless steel construction.

- 3000 Twisted-Wire Inserted-Eye Heddles: easy to thread, low friction.

- Compu-Dobby°: computerized-dobby pattern system makes pattern programming and changes a snap.

- WeavePoint IDL Design and Control Software: special version allows programming of Flyshuttle system.

- Installation and Training (continental U.S.). Comprehensive 3 days of install and training.

- 2-Year AVL Warrany

- Lifetime AVL support via phone, email, video chat.

- 1-Year Subscription to Handweaving.net

Options & Additions

- Drop Wire System

- Sectional Beam

- Plain Beam

- Automatic Bobbin Winder

- Powered Freestanding Beam Winder

Specifications

| Width (in reed) | Full Width | Front to Back | Height | No. of heddles | No. of harnesses | |

| Sample Loom | 24" (61 cm) | 79" (200 cm) | 77" (196 cm) | 75" (190 cm) | 3000 | 24 |

| Production Loom | 40" (102 cm) | 98" (249 cm) | 77" (196 cm) | 75" (190 cm) | 3000 | 24 |

| Production Loom | 60" (152 cm) | 118" (300 cm) | 77" (196 cm) | 75" (190 cm) | 3000 | 24 |

| Production Loom | 72" (183 cm) | 130" (330 cm) | 77" (196 cm) | 75" (190 cm) | 3000 | 24 |

Electrical and Air Requirements:

| Specification | Type | Estimated Consumption Value |

| Electrical - Control System | 110V / 220V | |

| Electrical - Compu-Dobby | 110V / 220V | |

| Pneumatics - All | 115 PSI | 25 CFM |

Notes:

1) Air consumption will vary according to the speed at which the loom is operated.

2) We recommend using a compressor with 100% duty cycle ratings. An alternative is a compressor with 50% duty cycle capability rated at 50 CFM @ 115 PSI.

Additional Links:

Recommended Air Dryers for Air Compressors

Made in Chico, California, USA

- Reviews